A different look at the quarter-inch hole

Sometimes the problem at hand drives the level of abstraction. In these instances, we need to look at Jobs-to-be-Done horizontally

Many of you have probably seen this quote from former Harvard Business School professor Theodore Levitt...

People don’t want to buy a quarter-inch drill. They want a quarter-inch hole!

While he stated this back in the 1960's, I still see many people today get stuck on what he was saying. Those who are new to Jobs-to-be-Done Theory (Jobs Theory) get stuck on this as they attempt to understand the Jobs in their lives, or in the work they do for their customers.

Almost everyone contemplates the purpose of the hole. Was it to join two pieces of wood with a bolt? Was it to hang a shelf? Is the user ultimately trying to decorate their home? We could go on forever. There are many reasons why someone might want a quarter-inch hole. Depending on the ultimate purpose of the hole…

There could be competing types of drills or bits

There could be competing ways to fasten whatever is needs to be fastened, e.g., purpose-built clips, glue, self-tapping screws, etc.

If it's a fastening solution it's also possible that one of the materials being fastened has a fastening solution built-in, eliminating the need for a quarter-inch hole altogether

Levitt wasn't trying to solve every problem with a single statement. He was using an analogy to explain the perspective we need in order to solve problems. In his case, he was speaking to marketers; but the lesson applies equally well to all problem-solvers.

Context is important

If we're going to solve a problem, we might need to understand the context. While a quarter-inch drill is a solution, so is a quarter-inch hole if your problem is at a higher level of abstraction. If it's not at a higher level of abstraction, you can focus on perfecting the creation of quarter-inch holes - the ability to make them faster and more accurately.

Given your specific problem (or solution) you can use techniques like Five Whys to search for the ultimate goal of your solution. The key is to stop where the next level is not actionable for your purpose, e.g., no capabilities, no authority, etc. As you continue to climb the levels of abstraction, you move closer and closer to pure aspiration...and this is the space where most of the Jobs-to-be-Done novices congregate as though they were led there by a Judas Goat.

If you frame a problem where there can be no actionable solutions - no technology, or an infinite number of possibilities - then you are misusing Jobs Theory, even if it makes you feel good in the moment.

One way to make this simpler is to apply a context to your problem. For example, my customer is a DIYer who is trying to join two pieces of plywood at a 90-degree angle

Higher level of abstraction not needed

I was recently working on DIY project custom-building a storage solution for a walk-in closet. To make the joints hidden, strong, and seamless I used a Kreg Jig1. It's designed to pre-drill angled pocket holes so you don't split the wood, create a strong joint, and hide your work. As I continued to use this setup it suddenly dawned on me that the package I bought had almost everything I needed to get the entire job done. Let's have a look at what it included:

The jig - clamps to material and provides control over the placement of the drill bit and configured for the thickness of the material

The material thickness gauge2 - gives you the input you need to set up the job and the drill bit collar. It also has a hex wrench built-in to tighten the drill bit collar

The drill bit3 - there are multiple solutions built into one. It drills the pocket hole, it drills a pilot hole for the pocket screw, it accepts a stop collar which can be set to the thickness of the material (ensures you don't drill too deep)

The stop collar4 - this mounts on the drill bit and controls the depth of the hole

Pocket screws5 - they give you a set in the package.

6" driver bit6 - the pattern fits the pocket screw

Clamp7- it’s just a basic wood clamp, but I didn’t have to go buy one myself

What’s not included:

A drill - most people have them anyway

A level - to assist when mounting the piece, e.g., a shelf in a storage cabinet

Wood putty - to fill in the pocket holes

Sandpaper - to remove and smooth excess putty

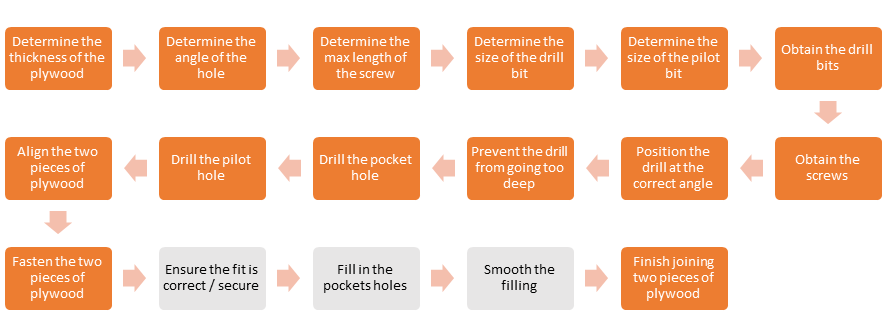

We’re talking about a problem this is extremely close to the solution-space. As a result, the Job is going to be a bit more granular than a higher-level core job. Basically, that means there are more steps, and the following is a strawman map (a draft for discussion) for the job a DIYer has when trying to join two pieces of plywood at a 90-degree angle.

The purpose of this demonstration is to emphasize that most solutions only get part of the job done, some solutions attempt to get more of the job done, and very few get the entire job done. This solution-set gets most of the job done, but not all of it.

If you look at the job map, you’ll see that the only steps that are not addressed by the Kreg Jig package that I purchased are after the execution steps (e.g., drilling). What you might have noticed is that each part in the package played dual roles (getting multiple steps done in a single solution). The package is a proxy for platform. You will often see me say that the goal of a solution provider is to help get the entire job done on a single platform.

The box it came in is what I use to store everything when I’m done, which addresses the last step

Kreg has taken steps to do that, at least for this specific type of work. It could possibly improve this even further by designing a single gadget that does more of the steps with fewer parts. Or possibly, they could offer plywood that has been modified to play a contributing role in some way, e.g., some substrate surfaces can accept paint better so the features don’t need to be added to the paint itself.

Of course, the first thing they could do is to help tradesmen fill in the pocket holes after the plywood has been fastened and then finish the surface by smoothing the roughness of the filling. A complete kit is worth the money, especially in situations like mine where I’m not a professional and I haven’t done this a thousand times.

I hope this helps you understand the quarter-inch hole dilemma a little more clearly.

Excelent article, Mike. For me, in the management consulting space, this is the main message: "The key is to stop where the next level is not actionable for your purpose, e.g., no capabilities, no authority, etc. As you continue to climb the levels of abstraction, you move closer and closer to pure aspiration". This is where most novice consultants and not so novice clients congregate.

It is interesting to notice that your reasoning runs parallel to the advice given by Saras Sarasvathy (Effectuation) to entrepreneurs: start with your means, and with what is under your control, and use them to define your goals. This is a powerful enabling content for chosing the job we are going to tackle.

I might have pointed out that Kreg may have isolated their job to Drill a pocket hole, while I took it up one notch. This gives them some more room for horizontal growth